Functional description and benefits

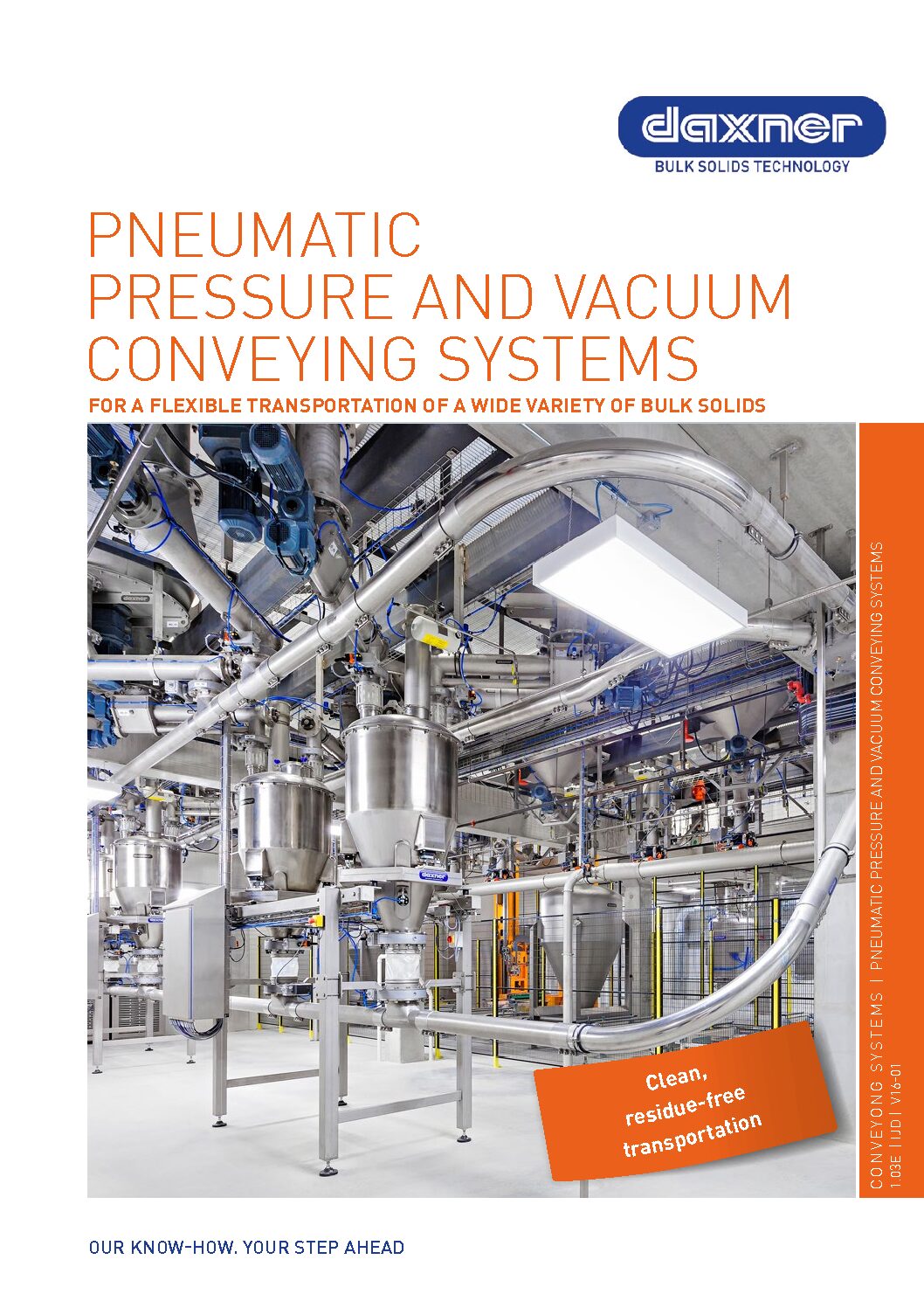

Pneumatic conveying systems via positive and negative displacement enable a flexible transportation of a wide variety of bulk solids. Customized solutions provide a clean and reliable operation by using high-end, well-tested components.

The material is either pushed or sucked through the pipeline by a positive or negative displacement blower located on the corresponding end of the pneumatic conveying system. Rotary air lock valves, injector nozzles or feed gates feed the product into the pressurized conveying line.

At the end of the conveying line, the material reaches the receiver bin where it is separated from the air. A filter cleans the exhaust air of residue dust particles. Filter designs vary from jet filters with filter hoses (high filter performance) to filter cartridges and can optionally be equipped with easy clean, inspection and filter exchange systems.

General features of pneumatic conveying systems are a flexible, clean and residue free transportation of a wide variety of bulk solids and multiple pick up/discharge locations.

Advantages

Customized system solutions made by our experts

Reliability and high performance by implementing high-end, well-tested system components

Transportation over long vertical and horizontal distances possible

Clean, residue-free transportation

Minimum space required

Optional easy cleaning features of system components

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.