Functional description and benefits

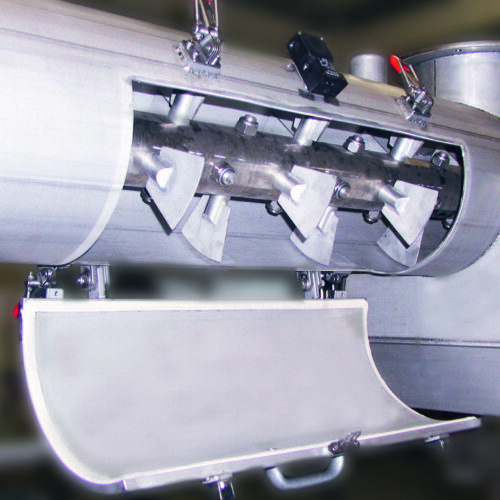

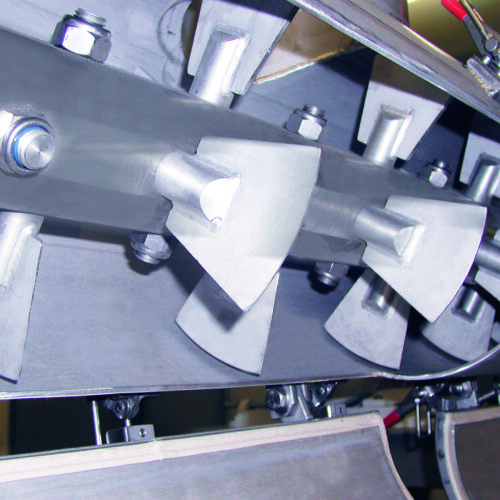

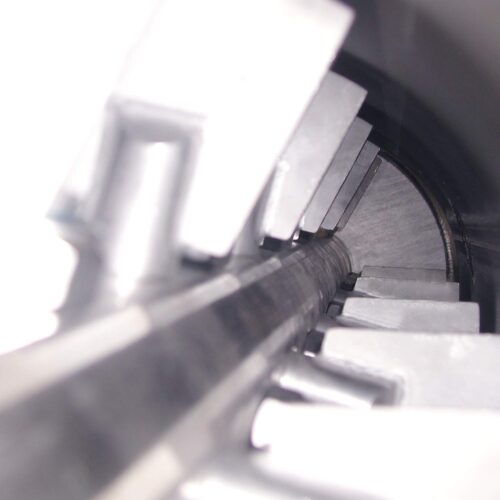

Hoizontal continous blenders achieve an excellent mixing accuracy and minimum particle degradation by means of adjustable paddles creating a three-dimensional “cross-flow” inside the mixer.

The adjustable and exchangeable paddles with different directions of flow blend the product gently while passing through the blender. New pre-dosed product is continously fed into the mixer. When the mixing process is finished the homogeneous product is discharged from the mixing chamber through the outlet.

The optional jacketed housing design makes these blenders ideal for the usage as an indirect heat exchanger (heating, cooling, drying). Large cleaning doors allow quick and comfortable access for cleaning and inspection.

Various sizes and design features allow custom designed solutions for specific material characteristics. Large cleanout doors guarantee quick cleaning and inspection.

Advantages

Customized design

For the lump free vortex mixing of carrier substance with liquids

Mischgenauigkeiten über 1:100.000

Gentle mixing

Temperature-controlled for the heating and cooling of product

Hygienic design with large doors for cleaning & inspection

Used for dry powders, pastes, doughs and suspensions

Robust design

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.