Description

Project objectives:

- Development of a plant and process technology for the production of pet food

- Optimization of sanitary regulations: utmost hygienic design of the plant

- Traceability of each component – in case a claim is registered, it can be detected which product was added during which time

- Improvement of the plant’s operational efficiency

- Quality improvement of the ready-made pet food

- Easy maintenance due to big cleaning lids; mainentance of the plant can performed without the use of any tools

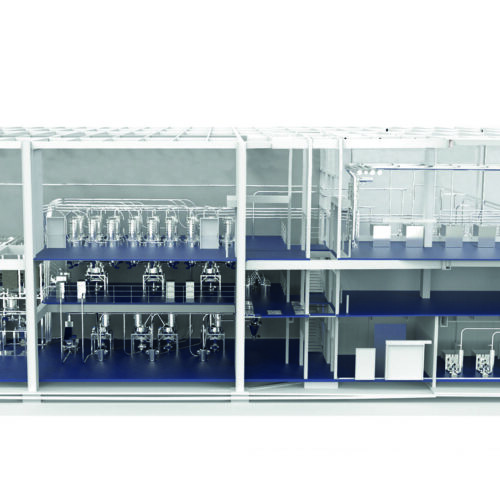

Process technology

The ingredients and inclusions are automatically dosed and fed to the wet mixers, in which the ready-made mixture of the product is produced.

Each raw material is loaded into the corresponding receiver bin in an unmixed condition. Below the receiver bin high-precision weighing hoppers are positioned, which enable an accurancy in the gram range. Subsquently the product is transfered to the cyclone separators through pneumatic conveying lines.

The implemented aspiration system ensures, that dust emissions are not generated by suctioning the dust while filling the containers. In the context of the occupational health and safety minimal MAC-values (maximum allowable concentration) can be achieved.

Innovative transfer system

A very special innovation of the pneumatic transfer system is the newly developed Daxner-injector system. This conveying system ensures the gentle intake and transfer of very fragile products. In the final stage of the transfer distance special separators are positioned, which were developed and optimized in various test series. These trials were performed with all products at Daxner’s headquaters. Also of significant importance is, that the implemented injector transfer substituted the conventional used dosing units (rotary valve).

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.