Modernization of a traditional milling company specialized in corn flour and healthy, organic products. The mill is certified as an Austrian producer of organic products with high requirements for its first-class product quality.

Description

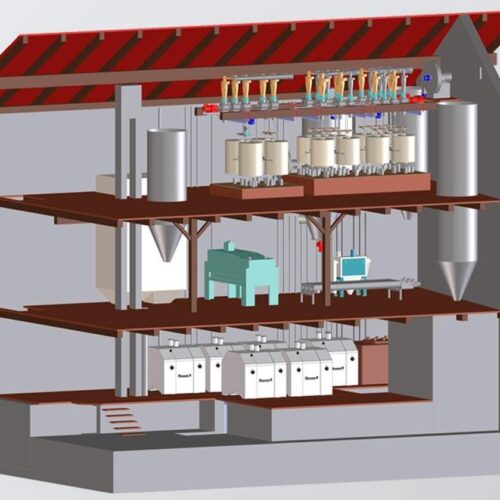

The mill runs on two separate milling systems:

- a combined wheat, rye and spelt mill for the production of various kinds of flour, meal, semolina

- a sweet corn mill for the production of polenta, corn flour and maize germ

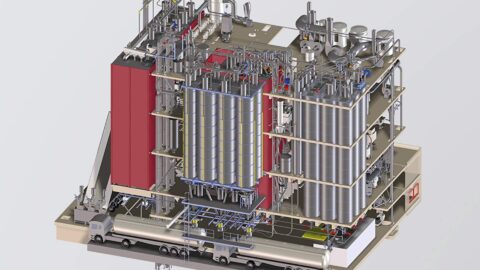

Before the modernization of the two milling systems, 10 to 12 tons was the daily maximum. The new milling design reaches a grinding capacity of 25 tons daily. To achieve this goal, Daxner assessed all possibilities to make room for expansion in the small milling facility.

Special focus was on optimizing the design to make use of the existing, although tight, space. The storage silos, flour mixers and bulk loading sections on site were integrated into the new efficient production process.

Especially the wide range of products offered by the mill posed as a big challenge. The innovative new build allows for the production of all variations of wheat, rye and spelt flours as well as organic speciality products. Moreover, a separate milling system produces different types of semolina which can – thanks to the modernization – now be operated simultaneously with the wheat, rye and spelt mill.

Major key points of the modernization

Easy clean:

The mill offers one cleaning system per milling system. The existing cleaning system was transferred in the conbined wheat, rye and spelt mill. Additionally, a used scrubbing machine with a capacity of 1,500 kg/h was integrated to enhance the purification process. In the sweet corn mill, the pre-cleaned product passes through a maize de-germinization facility which separates the fatty seedling from the grain.

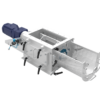

Roller mills:

The 6 new roller mills, model Phenomill, play an essential part of the two-way milling system. The combined wheat, rye and spelt gained 4 new roller mills (1 x 250/500, 3 x 250/600). Two lines run in sections on one pair of mills. The pair runs on a continous feed roll, the 2 pushers can be operated independently from eachother. The corrugating rolls run with a transmission ratio of 1:2.5; the smooth rolls with a ration of 1:1.25. The corrugation and corrugation positioning takes place according to diagrams.

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.