The successful bakery reached its capacity limits and invested in an innovative production facility with a high degree of automation. Technology from Daxner provides the handling of dry and liquid raw materials for two receiving stations.

Description

Together with the owner Daxner created a raw material weighing system which was tailored to the individual requirements of the bakery. The main focus was on a high degree of automation in raw materials provision to ensure the quality of the baked goods and also on a clear structure of the dough production area with particular attention to the essential issues – primarily hygiene.

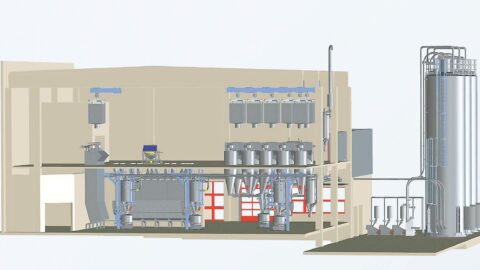

Silos

The silo facility, equipped with suction pneumatics for flour transport, consists of 4 external silos with 30 t capacity each and 4 internal silos with around 5 t of flour each. The containers in the cylindrical silos are welded in one piece using strong aluminium sheet segments.

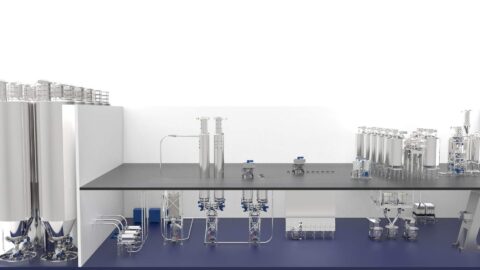

The flour is blown into the silos through a central filling station in the external area and then conveyed by 2 encapsulated aspirator fans into the 2 weighing containers – each with a capacity of 200 kilogrammes – which are installed in a room directly above the dough production. This is also where 2 dosing stations for small components are installed. Each is equipped with 8 stainless steel containers which can be easily filled with goods from bags from an access platform with steps and a safety rail.

They contain dry ingredients such as salt, raising agents as well as caraway and coriander, the bread spices typical of the Frankenland region. Each of the funnel shaped storage containers is equipped with its own frequency controlled conveyor screw in the lower section. This initially rotates at a higher speed to dose the main amount of the ingredient and then with slow rotations to carry out the fine measuring. The screw can achieve a weighing accuracy of about 10 grams.

The weighing units described are installed in duplicate and each supplies one receiving station in dough production – one for the bread range and the other for small baked goods and pastries. The dosed ingredients are transported through smooth downpipes, which offer little surface for dust to adhere, and the fixed extraction hood and finally into the vat. All supply lines for the liquid ingredients such as water, brine, liquid yeast and a creamy mass consisting of bread residue or wheat pre-dough are installed on the cover.

The water mixing and dosing system as well as the other storage containers for liquid components are housed in side rooms, leaving the rear wall of the dough production area to look very tidy. All supply lines exit from the wall in one central location which is clad with stainless steel. Only the swivel arm brackets for the 2 operator touch screens as well as the plug sockets for the telescopic spiral kneaders are visible on the tiled rear wall.

Liquid components

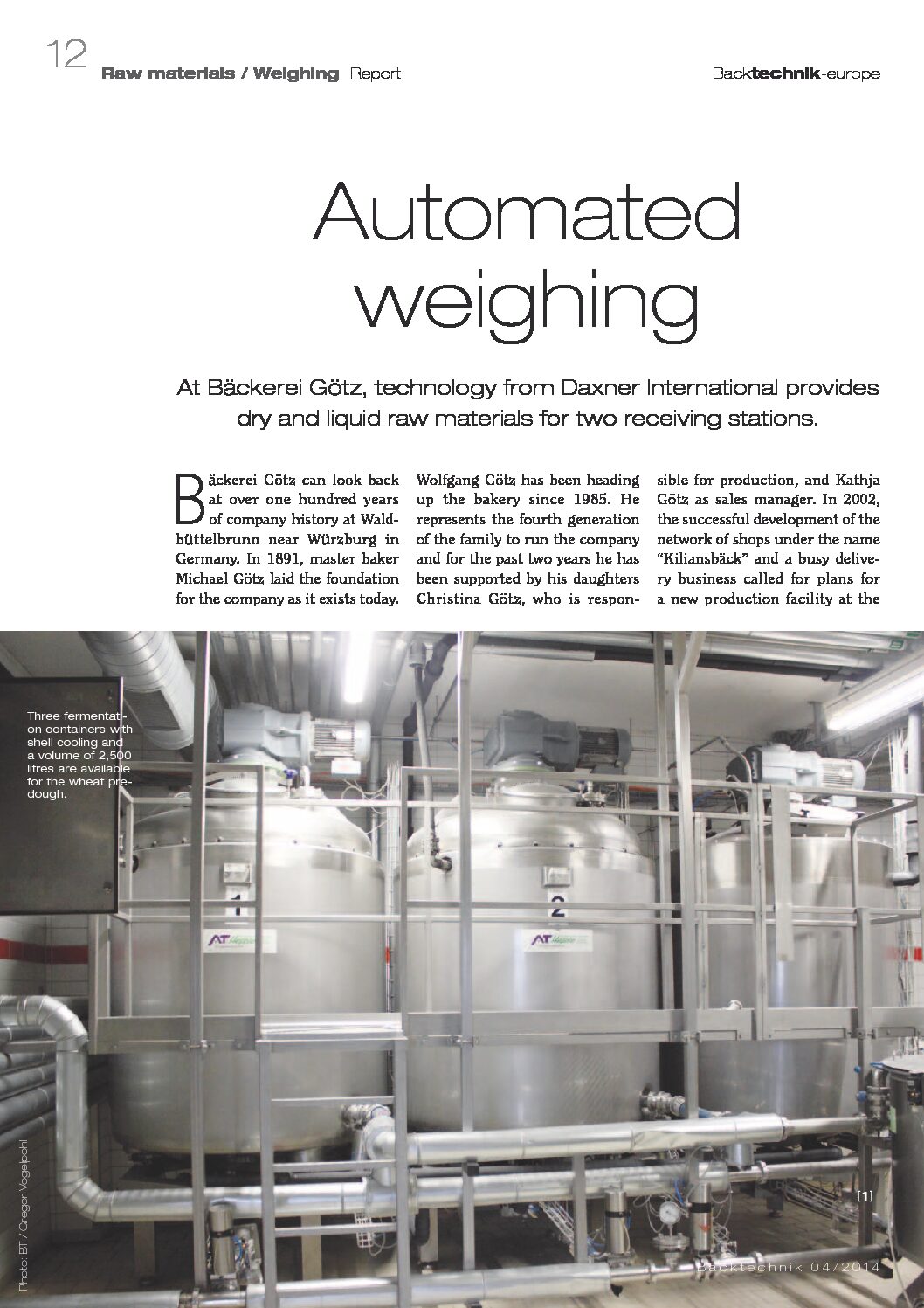

The room for pre-dough production and storage is located underneath the silo room, directly behind the dough production. The complex, fully automated plant essentially consists of 3 stainless steel proving and storage containers and the continuous Daxner pre-dough mixing system daxDou. This is used for intensive mixing of flour, water and additional ingredients – in this case the dough residue.

The pre-dough mixer is based on the principle of a continuous flow mixer and is equipped with kneading tools which were developed especially for dough production. The mixing tool can be moved out of the housing completely to facilitate cleaning. Wet cleaning is performed using an integrated high-pressure system via highpressure flat-spray nozzles. A container scale and a differential dosing scale are installed for continuous gravimetric flour addition. The dosing screw attached there continuously supplies the pre-dough mixer with the precise amount of flour and the water is dosed with a flow meter.

All systems are monitored and coordinated by the electronic control system. To ensure constantly fermented pre-doughs at any time of year, the double wall storage containers with 2,500 litres capacity each are equipped with a cooling water shell which is connected to a cooling water circuit. This allow precise control of all important dough parameters such as temperature, consistency and proving time using the computer control of the pre-dough mixing system.

A durable stainless steel mixer is attached to each of the proving containers. These mix the wheat pre-dough at fixed intervals and also allow processing of pre-doughs with low dough yield (dough yield of approx. 170). The tanks are filled from underneath so that no dough encrustations or flour dust can accumulate in the upper section.

Recently the bakery has also been processing bread residue into a ready-to-use creamy mass. A special process is used to liquidise the bread residue in the daxRec with a minimum amount of water and then crush the mixture in a rotor stator system using a special fine grinding technology. This creates a suspension which can be pumped and will not separate again, greatly facilitating storage in a cooled container.

Conclusion

Clear structures were created from raw materials receipt through to delivery and the individual production plants are set up in line. The compact size of the entire raw material supply section is also impressive.

Technology

- 4 external silos 30 tons

- 4 internal silos 5 tons

- 2 identical small component dosing stations

- daxDou continuous pre-dough mixer

- daxRec for processing bread/dough residue

- daxSol brine system

- yeast dissolver

- 3 fermentation containers with shell cooling and a volume of 2,500 litres

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.