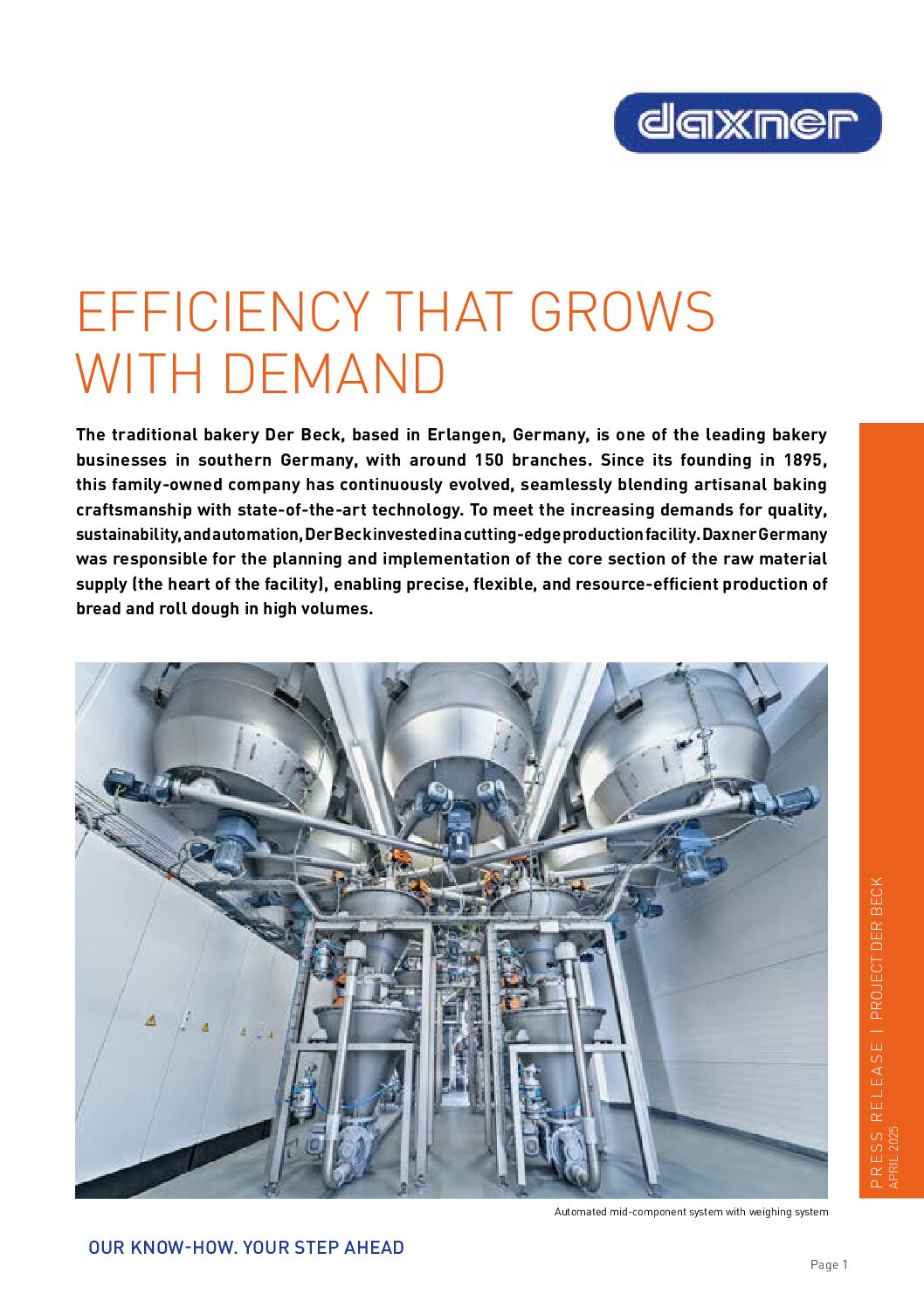

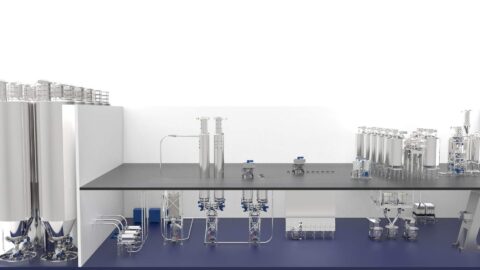

The traditional bakery `Der Beck´, based in Erlangen, Germany, is one of the leading bakery businesses in southern Germany, with around 150 branches. Since its founding in 1895, this family-owned company has continuously evolved, seamlessly blending artisanal baking craftsmanship with state-of-the-art technology. To meet the increasing demands for quality, sustainability, and automation, Der Beck invested in a cutting-edge production facility. Daxner Germany was responsible for the planning and implementation of the core section of the raw material supply (the heart of the facility), enabling precise, flexible, and resource-efficient production of bread and roll dough in high volumes.

Description

Maximum capacity with optimal flexibility

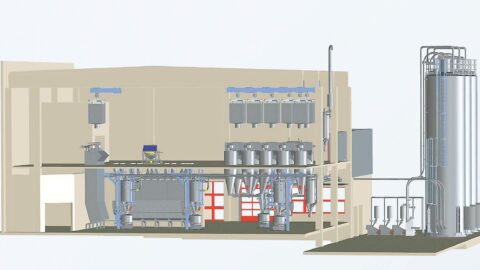

The new production line in Erlangen stands out due to its impressive performance capabilities. Six external silos, each with a gross volume of 62 m³, ensure the efficient storage and processing of both light wheat flour and darker rye and Ruch flours. The facility operates on a two-shift system, running 365 days a year, ensuring maximum production capacity. Additionally, the silo space has been pre-configured for an expansion of two additional silos.

The facility includes two separate production lines: one dedicated to bread, with a capacity of 16 batches per hour at 250 kg of dough per batch, and another for rolls, processing 20 batches per hour with dough volumes ranging from 170 to 250 kg per batch. In total, the facility can handle up to 9,000 kg of dough per hour.

Precise dosing and efficient raw material management

A key success factor is the precise dosing of ingredients. Daxner Germany has implemented a mid- and micro-component system, consisting of eleven mid-component silos (2,500-liter gross volume) and eleven micro-component silos (500-liter gross volume). All silos are equipped with dual discharge systems to serve both the bread and roll production lines. Thanks to intelligent control systems, loss-free and highly precise raw material management is ensured. Expansion with three additional silos per category can be easily accommodated.

Innovative automation solutions for maximum efficiency

The weighing stations for both production lines are equipped with the latest technology. Multiple flour weighing units feature weigh hoppers with a capacity of 200 kg, while stainless steel water dosing systems handle three different types of water. Additionally, floor scales with a capacity of up to 800 kg facilitate manual component weighing, complemented by high-performance flour dust extraction systems. These measures ensure both high precision and hygienic safety. A critical component of the production process is the pre-fermentation and sourdough system. The continuous dax-Dou 3.1 allows for combined use with both rye and wheat doughs. Two sourdough tanks for rye (each 3,000 liters) and two pre-fermentation tanks for wheat (4,000 kg/day) ensure consistent fermentation results. Pigging systems ensure nearloss- free dosing of the doughs.

Higher product quality through smart control and ergonomic design

Another highlight of the facility is the RFID-based guidance system for mixing bowls, which manages dough resting times and ensures precise monitoring of bowl contents. This results in greater transparency and security in the bakery’s production process. The entire system is controlled via the proven Optidos Profi solution from Bornträger, enabling intuitive operation, optimized raw material management, and precise control of fermentation processes. Ergonomically optimized workflows for weighing and dosing further contribute to increased efficiency.

Sustainability as a core element

In addition to boosting productivity and quality, the project placed a strong focus on sustainable solutions. The use of pigging systems ensures that pipelines are completely emptied, minimizing raw material losses. The innovative daxRec leftover bread crusher reintegrates unsold or defective baked goods directly into the production process, significantly reducing food waste. An automated cleaning program for the sourdough system’s fermentation tanks and pipelines ensures consistently high hygiene standards while minimizing labor requirements.

Scalability and a benchmark for the industry

From the outset, the new production facility was designed with scalability in mind. Additional fermentation tanks can be seamlessly integrated into the existing system. The digital visualization of the entire facility further enhances transparency, enables rapid fault detection, and ensures efficient process control. With this cutting-edge production line, Der Beck in Erlangen is investing in a sustainable and future-proof technology that not only enhances efficiency and product quality but also conserves resources and contributes significantly to sustainable food production. With this facility, Daxner Germany once again demonstrates its innovation and technological excellence in the field of modern bakery equipment.

Key components

for this solution

Dosing & Weighing

- Central vacuum cleaning systems

- Tanker truck screening machine | Inline screening machine

- Dosing & Screening machine DM30 Easy Clean

- Control screening machine VIB & PRESS

- Weighing bin

- Dosing screw conveyors

- Dosing systems for medium and small batches

- Combined bag intake & Big bag discharge station

- Diverter valves and accessories

- Pneumatic pressure and vacuum conveying systems

- Tubular screw conveyors | Dosing screw conveyors

- Big bag discharge docking system

Big bag handling

- Central vacuum cleaning systems

- Dosing screw conveyors

- Dosing systems for medium and small batches

- Combined bag intake & Big bag discharge station

- Diverter valves and accessories

- Pneumatic pressure and vacuum conveying systems

- Tubular screw conveyors | Dosing screw conveyors

- Big bag discharge docking system

- Big bag loading system Eco Basic

Mehr Lösungen für Backwaren

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.