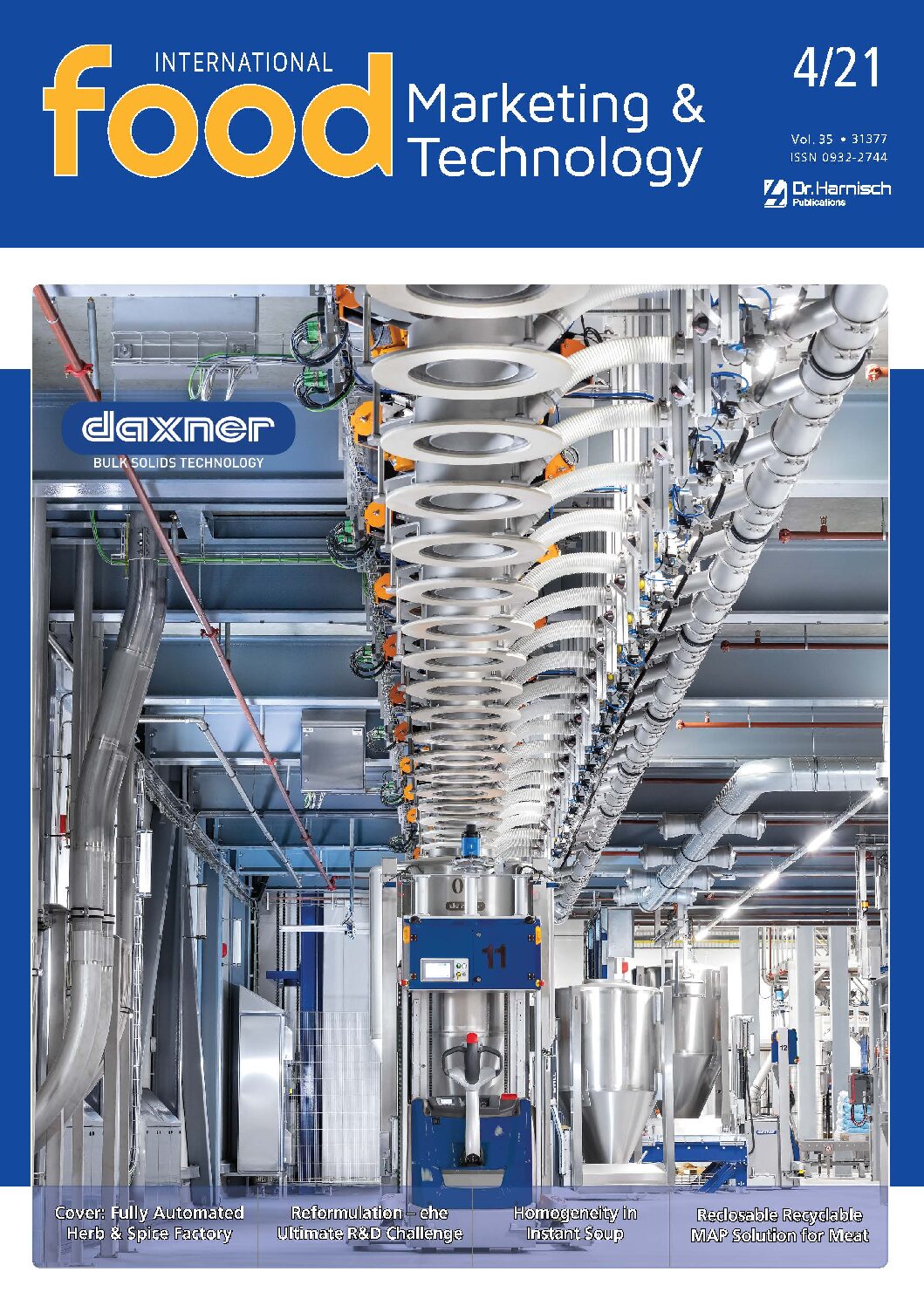

As one of the leading producers of high-quality herb and spice mixtures as well as texture solutions, they contracted Daxner from Wels (Austria) with engineering, fabrication and installation of a fully automated plant solution centering around the well-proven Daxner Container Handling System DCS.

Description

The showcase plant was taken into operation in 2019. It was built on an area the size of 5 soccer fields, houses a 29 m high bay storage and was awarded the BREEAM Excellent Sustainability Certificate.

First and foremost the plant enables the company, known as pioneer of gentle herb processing, to increase the production volume and reach a new level of food safety. The Company aims to unify the entire dries processing of all existing factories at the new production site.

Fully automated Container Handling System DCS

The technically impressive plant design guarantees a high throughput performance and dosing accuracy. The possibility of cross contaminations and dust formation was reduced to a minimum.

According to the hygienic design requirements, all components were executed in stainless steel and designed for easy cleaning. Perfectly in sync with the fully automated Daxner Container Handling System DCS, laser operated Automatic Guided Vehicles AGV make their way through the production facility to collect the valuable dry components. The raw components are divided into large, middle and small components. Large components, like wheat flour or potato and corn starch, are delivered in tanker trucks and stored in 12 large outdoor silos. A pneumatic vacuum conveying system transports them to the day bins within the plant.

Mobile bag and big bag intake stations

The filling of large and middle components into day bins happens with mobile bag and big bag intake stations. Below the day bins, highly precise scales were installed. Depending on the product‘s qualities, separate day bins as well as weighing systems are assigned accordingly. This exact allocation avoids cross mixing with any allergenic raw materials. Once all of the separate raw materials are dosed into the weighing bins, the collection process with the Daxner Container Handling System DCS combined with the Automatic Guided Vehicles AGV commences. One AGV, loaded with a 1,500 liters container, drives from weighing bin to weighing bin and fills itself with the pre weighed raw materials. This concept saves time: As soon as one raw material component is picked up, the weighing bin can dose the batch for the next container immediately.

Supplying the small and minor components

The manual feeding of the containers for small and minor components happens on the ground floor.

According to the goods-to-man-concept, all ingredients are brought to the operator: the containers with the AGV, the small components in bags on pallets and the pre-commissioned minor components

in crates from the minor components storage (MCS). Therefore, the system achieves a time optimized supply of all components without unnecessary ways for the operator. Once all components are fed into the container, it continues its fully automated path to the assigned mixing line. The container is transported to the container elevator with the help of an AGV and lifted onto the floor above the blender. From there, another AGV picks it up and sets the container precisely above the respective blender. Not only the opening of the latch but also the emptying of the blender happens without the help of an operator. After the blending process of herbs, spices and other ingredients, a quality control of all products is conducted. The finished mixes are weighed and filled into mounted big bags and fed into the according packaging lines.

Great flexibility with various blender types

Blenders with a capacity of 1,500 up to 10,000 liters are used. There are multiple ways of filling the blenders: directly from the outdoor silos, with containers or through liquid dosing. After blending, the product is emptied directly into one of the downstream containers. Blender and container sizes are an optimal match and offer immense flexibility when it comes to possible batch sizes. This freedom in design emphasizes another highlight of this plant: a container blender with a volume of 1,500 liters

where the mixing happens directly in the container. The advantage for the user: one saves a whole process step because the filling process into the blender is cut out completely.

Packaging of the finished mixes

After the blending process, an Automated Guided Vehicle collects the containers with the finished mixes and transports them without manual help to the discharge station which is located next to the bag filling station. The gravimetrical bag filling and weighing system DAX-PVS (Pinch Valve System) fills the finished mixes into sales packaging. The core components of the DAX-PVS systems are the pneumatically operated pinch valves which guarantee the exact dosing of the products.

Fulfills HACCP and IFS

The complete blending and packaging line is equipped with an aspiration system which reduces dust formation to a minimum. The central dedusting system guarantees easy and comfortable cleaning of the whole facility. Furthermore, the system fulfills the requirements for IFS and HACCP.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.