The traditional bakery `Der Beck´, based in Erlangen, Germany, is one of the leading bakery businesses in southern Germany, with around 150 branches. Since its founding in 1895, this family-owned company has continuously evolved, seamlessly blending artisanal baking craftsmanship with state-of-the-art technology. To meet the increasing demands for quality, sustainability, and automation, Der Beck invested in a cutting-edge production facility. Daxner Germany was responsible for the planning and implementation of the core section of the raw material supply (the heart of the facility), enabling precise, flexible, and resource-efficient production of bread and roll dough in high volumes.

Description

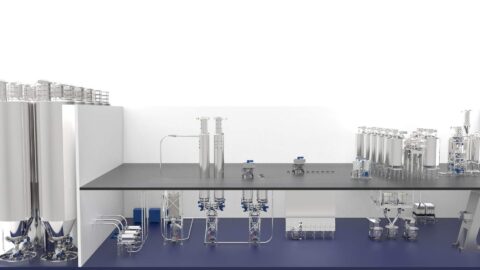

Maximum capacity with optimal flexibility

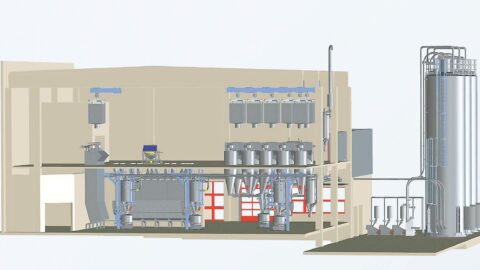

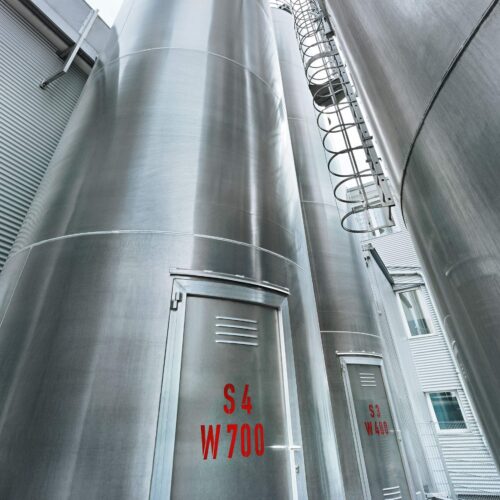

The new production line in Erlangen stands out due to its impressive performance capabilities. Six external silos, each with a gross volume of 62 m³, ensure the efficient storage and processing of both light wheat flour and darker rye and Ruch flours. The facility operates on a two-shift system, running 365 days a year, ensuring maximum production capacity. Additionally, the silo space has been pre-configured for an expansion of two additional silos.

The facility includes two separate production lines: one dedicated to bread, with a capacity of 16 batches per hour at 250 kg of dough per batch, and another for rolls, processing 20 batches per hour with dough volumes ranging from 170 to 250 kg per batch. In total, the facility can handle up to 9,000 kg of dough per hour.

Precise dosing and efficient raw material management

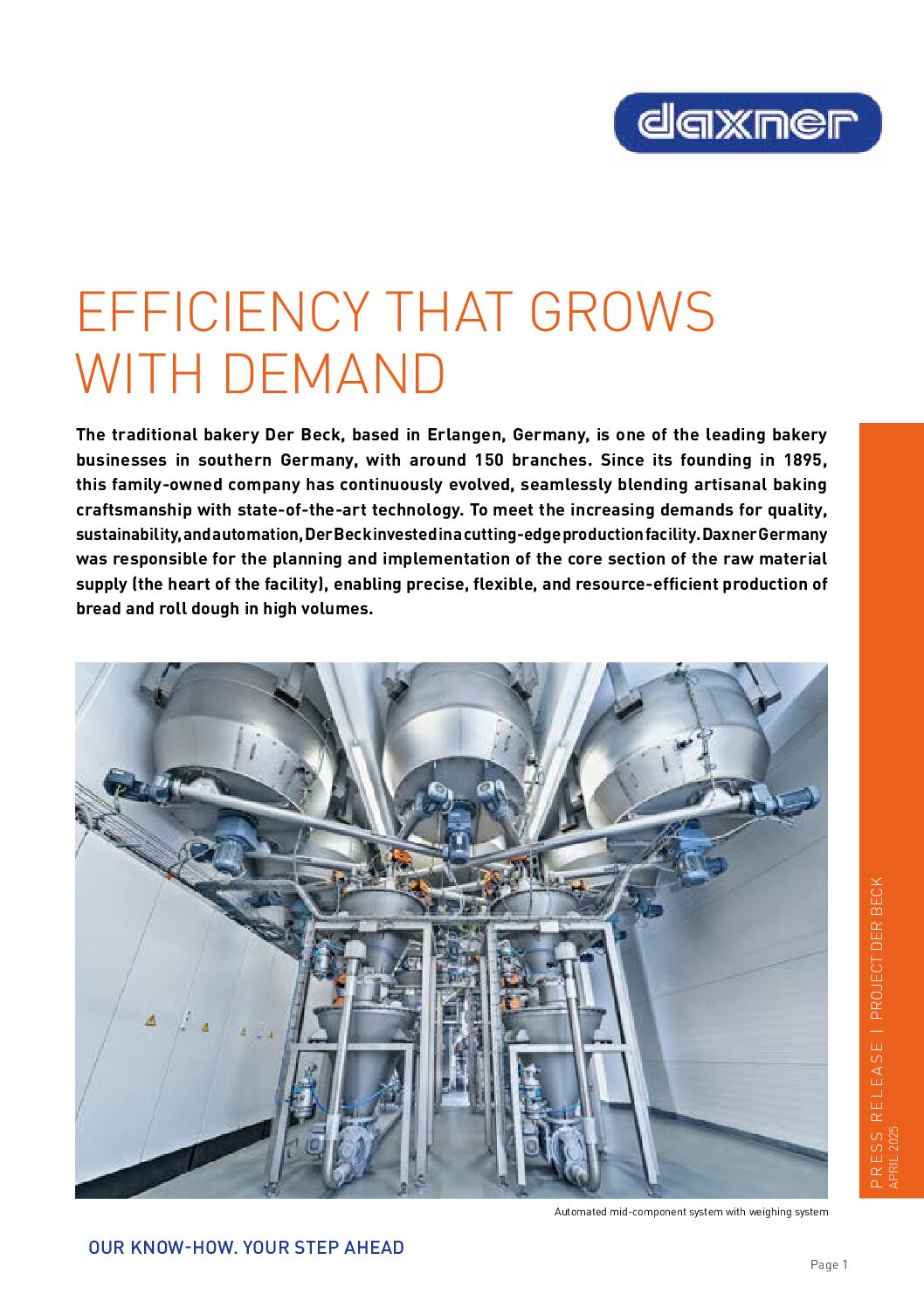

A key success factor is the precise dosing of ingredients. Daxner Germany has implemented a mid- and micro-component system, consisting of eleven mid-component silos (2,500-liter gross volume) and eleven micro-component silos (500-liter gross volume). All silos are equipped with dual discharge systems to serve both the bread and roll production lines. Thanks to intelligent control systems, loss-free and highly precise raw material management is ensured. Expansion with three additional silos per category can be easily accommodated.

Innovative automation solutions for maximum efficiency

The weighing stations for both production lines are equipped with the latest technology. Multiple flour weighing units feature weigh hoppers with a capacity of 200 kg, while stainless steel water dosing systems handle three different types of water. Additionally, floor scales with a capacity of up to 800 kg facilitate manual component weighing, complemented by high-performance flour dust extraction systems. These measures ensure both high precision and hygienic safety. A critical component of the production process is the pre-fermentation and sourdough system. The continuous dax-Dou 3.1 allows for combined use with both rye and wheat doughs. Two sourdough tanks for rye (each 3,000 liters) and two pre-fermentation tanks for wheat (4,000 kg/day) ensure consistent fermentation results. Pigging systems ensure nearloss- free dosing of the doughs.

Higher product quality through smart control and ergonomic design

Another highlight of the facility is the RFID-based guidance system for mixing bowls, which manages dough resting times and ensures precise monitoring of bowl contents. This results in greater transparency and security in the bakery’s production process. The entire system is controlled via the proven Optidos Profi solution from Bornträger, enabling intuitive operation, optimized raw material management, and precise control of fermentation processes. Ergonomically optimized workflows for weighing and dosing further contribute to increased efficiency.

Sustainability as a core element

In addition to boosting productivity and quality, the project placed a strong focus on sustainable solutions. The use of pigging systems ensures that pipelines are completely emptied, minimizing raw material losses. The innovative daxRec leftover bread crusher reintegrates unsold or defective baked goods directly into the production process, significantly reducing food waste. An automated cleaning program for the sourdough system’s fermentation tanks and pipelines ensures consistently high hygiene standards while minimizing labor requirements.

Scalability and a benchmark for the industry

From the outset, the new production facility was designed with scalability in mind. Additional fermentation tanks can be seamlessly integrated into the existing system. The digital visualization of the entire facility further enhances transparency, enables rapid fault detection, and ensures efficient process control. With this cutting-edge production line, Der Beck in Erlangen is investing in a sustainable and future-proof technology that not only enhances efficiency and product quality but also conserves resources and contributes significantly to sustainable food production. With this facility, Daxner Germany once again demonstrates its innovation and technological excellence in the field of modern bakery equipment.

Key components

for this solution

Dosing & Weighing

- Central vacuum cleaning systems

- Tanker truck screening machine | Inline screening machine

- Dosing & Screening machine DM30 Easy Clean

- Control screening machine VIB & PRESS

- Weighing bin

- Dosing screw conveyors

- Dosing systems for medium and small batches

- Combined bag intake & Big bag discharge station

- Diverter valves and accessories

- Pneumatic pressure and vacuum conveying systems

- Tubular screw conveyors | Dosing screw conveyors

- Big bag discharge docking system

Big bag handling

- Central vacuum cleaning systems

- Dosing screw conveyors

- Dosing systems for medium and small batches

- Combined bag intake & Big bag discharge station

- Diverter valves and accessories

- Pneumatic pressure and vacuum conveying systems

- Tubular screw conveyors | Dosing screw conveyors

- Big bag discharge docking system

- Big bag loading system Eco Basic

Mehr Lösungen für Backwaren

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

New bakery production line improves capacity

A renowned producer of baked goods and long-term customer of Daxner extended its successful production facility in Upper Austria. Besides 5 new outdoor silos, the plant was upgraded to 4 production lines.

Description

Silos

Firstly, the flour arrives in tanker trucks. Pneumatic pressure conveys it into the designated outdoor silo.

An aeriation system mixes and loosens up the flour in the silo funnel. This way, the flour can easily be transported out of the silo into the screening station. Two pressure blowers located in a room next to the outdoor silos enable the pneumatic conveying of the product.

Raw material intake and conveying

2 centrifugal screeners screen the flour to dispose of any unwanted coarse product. The fine product continues on to either production line 4, the day silo for rye flour or the weighing bin for the wheat sour dough.

There, the wheat flour is weighed before a screw mechanically conveys it to the kneader. If needed, dusting flour can be extracted at the screw’s outlet.

Baking aids and salt enter the production process via Big bags or bags that are emptied at the bag intake station. Some of the ingredients continue directly to the weighing bin before reaching the kneader. Moreover, liquid yeast and oil are added from the on-site liquids station on production line 4.

The medium components station in line 4 consists of several Big bag discharge stations with conveyor screws. The ingredients are sieved through the built-in screen of the bag intake station before a screw conveys the material to a weighing bin.

A double screw transports salt and the rye flour from the day bin to the weighing bin. The sieved flour from the centrifugal screener is stored in the day bin for rye or before entering the weighing bin.

The dusty air is cleaned by an aspiration filter The cleaned air exhausted back into the facility.

Soaker system

The soaker system consists of a Big bag discharge station, day bins, a weighing bin and a conveyor screw. This is where linseeds, oats, sunflower seeds and malt flour are conveyed pneumatically from the Big bags into the day bins.

The Big bag outlet is connected to the Big bag discharge system where the medium components enter the bag intake station to be sieved by the control screening machine. Afterwards, a diverter valve conveys the bulk solids into the respective day bin. According to the recipe at hand, the medium components are transported via vibro bin dischargers to the screws. Next, a screw conveyor transports the weighed product to the soaker mixing bin.

The water supply comes from a water mixer containing tap water, hot water or ice water.

Wheat sour dough system

The water mixing system supplies the wheat sour dough blender with water. The scale of the mixing container serves as control weighing unit.

Flour from the outdoor silos reaches the weighing bin positioned above the mixing container via a pneumatic conveying line. A rotary valve and a piping system transport the goods from the weighing bin to the mixing container.

The homogenous blend continues to the storage tank via a pump. The sourdough starter is added over a separate insulated and cooled preparation tank.

Metal detection system

The metal detection system is located shortly before the packing station. The finished baked goods passes through the system on a conveyor belt to detect any ferrous parts.

Key components

of this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

High performance plant solution for rye sour dough & wheat sponge

An important success factor of this renowned pre-bake manufacturer is its consistent use of rye sour dough and wheat sponge in its bread and biscuit production. For its further expansion, the company relies on the technology supplied by Daxner. Working on a 3-shift cycle, 500 employees process approximately 30 t of rye sour and 45 t of wheat sponge a day.

Description

Sour dough

Daxner installed 10 additional fermentation tanks with a capacity of 2,500 l which continuously supply production with sour dough. First of all the individual components must be mixed in one of the two 2,000 l mixers. Like the fermentation tanks the mixers also have a 3-wall outer cover. Therefore, if all fermentation tanks are filled, they can be converted into a storage location. This increases the flexibility of production.

First of all the required quantity of flour or coarse meal is weighed and then added through a direct connection to the mixer. A separate pipe is also installed for the necessary water. Also linked to the mixers are the two tanks in which the storage leaven is produced separately and stored. When all components are in place the mixer starts to move and mixes the individual ingredients thoroughly.

Then the sour dough is pumped into an empty tank for fermentation. A dedicated extraction pipe is available for each type in order to avoid any cross-mixing. The fermentation tanks are also naturally equipped with a stirring discharger to keep the rising sour dough moving and thus to reduce the volume. The sour dough is then transported by type through further separated pipes to the weighing stations where smaller storage tanks are installed and from which the sour dough and other liquid components may be requested. This action speeds up the weighing, because the individual ingredients do not have to be transported long pipe distances.

Wheat sponge

The bakers require about 45 t of wheat sponge per day which are prepared in a Daxner system. Two weighing scales operating one behind the other ensure the batch supply of the pre-dough mixer with flour. Whilst the required volume is being weighed in the upper weighing scale, the lower weighing scale can simultaneously supply the pre-dough mixer.

The liquid components of the wheat sponge are continuously made available and transported via the relevant connections to the mixing screw which generates a homogeneous mass. The wheat sponge then arrives in the fermentation tanks via a system of pumps and pipelines. After the fermentation period in the tanks the system pumps the wheat sponge into the 6,000 l capacity storage tanks. During this process a plate heat exchanger is interconnected and which cools down the wheat sponge by over 20 °C to the desired storage temperature. The whole system is time and temperature controlled and may be operated and controlled both by a control unit directly on the system and via the computer in the production office.

Cleaning is very important both for sour dough and for wheat sponge in order to avoid any subsequent spontaneaus fermentations. The respective tanks are cleaned with an automatic cleaning programme and the pipelines with a pig – pipe cleaning system. The system guides residues through the relevant pipes into the available drainage outlets.

Conclusion

Sour dough, wheat sponge and the processing of soakers give the bakery products their specific character manifested in a long freshness period and an individual aroma. These quality components are also attractive from a cost perspective since their use enables the use of baking agents to be reduced. Another factor in this success story is the flexible production process which is able to accommodate individual customer requests. To achieve these the modern technology in use is enhanced by manual activities in specific places.

The product range covers 35 g party rolls to large loaves. 500 employees work 24/7 on 13 production lines to produce the bakery products. The core competency of the company is the production of bread and bread rolls. Most of the production is frozen, either as pre-fermented dough or part-baked. The 9,000 industry standard range capacity of the deep freeze store enables production to produce large volumes which can then be buffered in the store.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

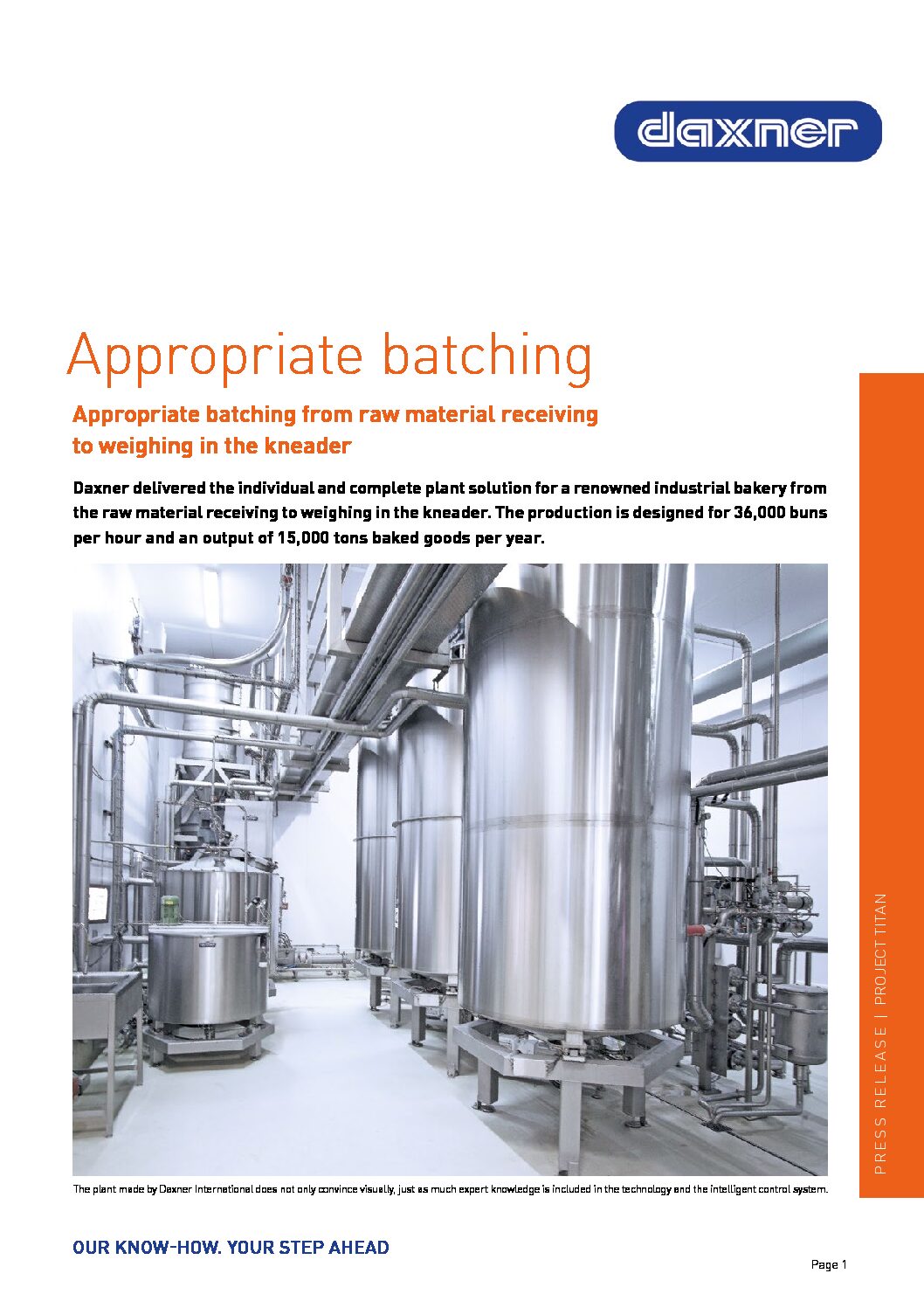

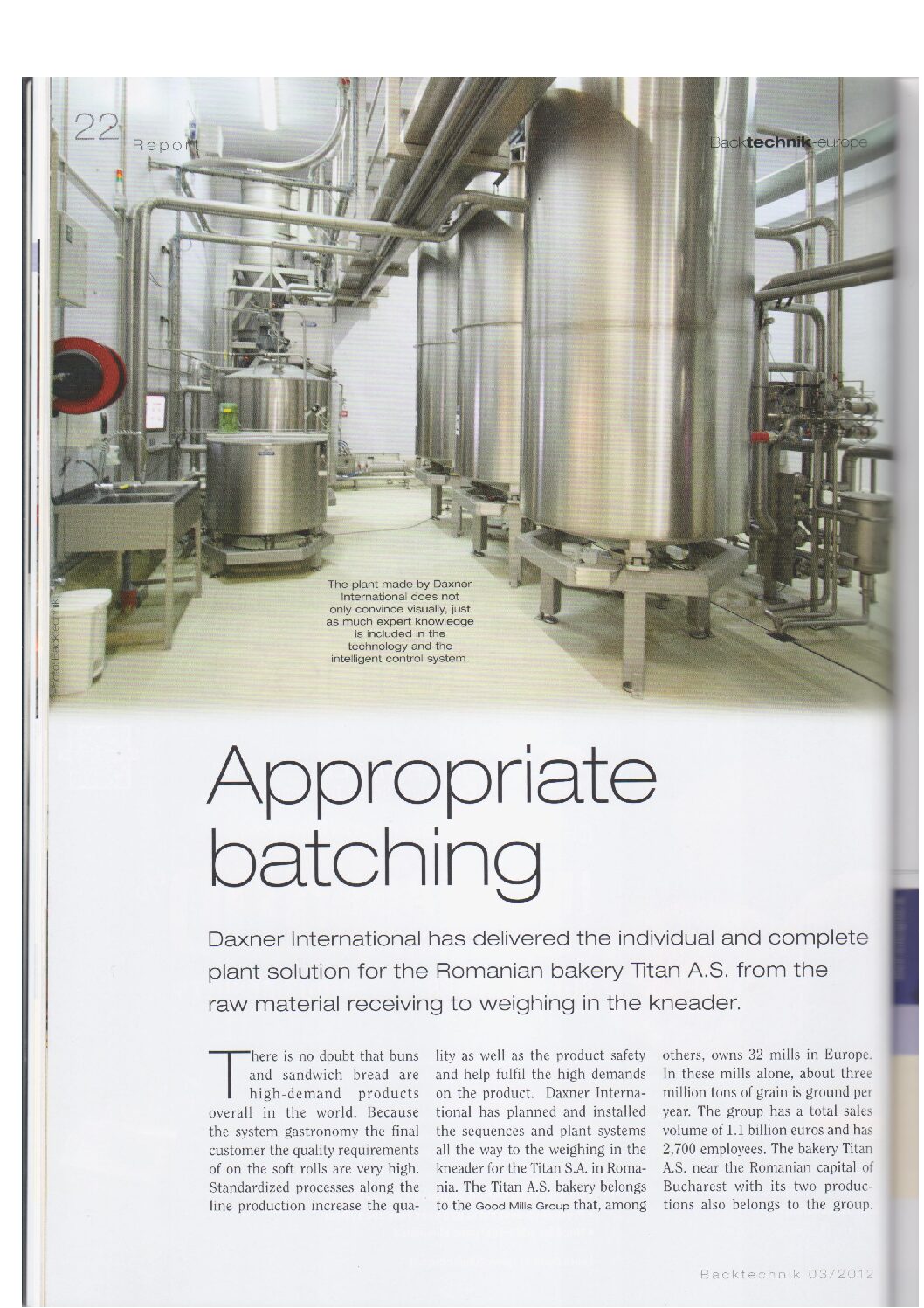

Appropriate batching from raw material receiving to weighing in the kneader

Daxner delivered the individual and complete plant solution for a renowned industrial bakery from the raw material receiving to weighing in the kneader. The production is designed for 36,000 buns per hour and an output of 15,000 tons baked goods per year.

Description

Raw material

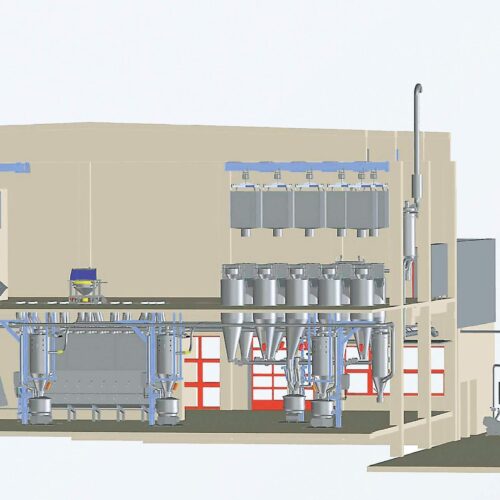

Strictly defined raw material characteristics are the absolute precondition for the uniform production of buns for the system gastronomy. All ingredients with their properties like temperature, charge size, supplier, date of supply and shelf life must be captured by the system. Therefore, each item receives its own identification in the goods receiving using a bar code with which it can be entered in the warehouse. lf the raw material is requested from the production area, an employee reads the raw material out again and transfers it into the production system. The system automatically performs usual queries, e.g. “first in first out” or minimum order quantities, and with this, it ensures a smooth process. Large quantity ingredients like flour and sugar are stored in outdoor silos of the bakery.

Three aluminium silos with a capacity of 50 tons each have been installed for the wheat flour delivered by the mill that belongs to the group. The sugar silo is made of stainless steel and has a capacity of 30 tons. All containers are placed on weighing cells that continuously report the fill level to the system and also serve for goods receiving control.

The oil, required for the production is stored in dedicated tanks. Two tanks each are connected to the conveying system. If a tank has been emptied, the system automatically passes over to the second tank and there will be enough time to provide the raw material from the warehouse. The most important reason for the selection of such an extensive warehouse management is, in addition to continuous availability, the traceability of the raw materials in the whole system. lt must be known which raw materials have been processed for each batch. Only in this way, the customers’ strict requirements on the company can be fulfilled. Among others, the bakery is controlled by the American Institute of Baking (AIB).

Starter dough and weighing

Great importance was placed on to a highly-automated line which is reflected, among others, by the weighing process and the production of the starter dough. All high-quantity ingredients are automatically fed into the system. The small-quantity ingredients are prepared manually.

One part of the dosing system is the yeast dissolver with a capacity of 500 liters. After a short agitating phase, shorter than ten minutes, the liquid yeast is ready to be pumped into the storage container right beside it. Now there is enough time to start the automatic cleaning program to clean the yeast dissolver and to prepare it for the next use.

The system receives the main ingredient of the starter dough, the wheat flour, from the external silos. At first, the specified quantity of flour is filled into a first scale. If the weight is reached, the flour is led to the second scale that is installed directly below the first one. While the starter dough is being mixed with the other ingredients, i.e. water, yeast, and oil, in the dough preparation unit, the first scale is ready again for providing the next batch. The dough is filled into two maturation tanks with a capacity of five tons each.

The starter dough tanks are filled from the bottom up. This design avoids dough deposits on the agitators and in the upper area of the fermenter. None of the three fermenters are filled with flour. This ensures the compliance with the hygiene standards because no flour dust occurs. At temperatures between 25°C and 30°C and a maturity period between two and eight hours depending on the operation, the dough has enough time to develop. The starter dough is moved in specified cycles to intensify the process of maturation.

After the end of the maturation period, the dough is pumped into storage containers. With this, the product goes via a plate heat exchanger that cools the mass down very fast to approximately 5°C. An important point of the dough production is the temperature of the ingredients that is also decisive for the final temperature of the finish-kneaded dough. For this reason, an extensive cooling system has been integrated that cools the individual ingredients down to the specified temperature. For this purpose, some tanks are designed as a triple wall structure to enable the coolant to circulate effectively. The storage container is designed in the same way to avoid the further development of the starter dough and to provide a stabile buffer for the production.

The ingredients fed into the kneader are weighed by a unit installed by Daxner. ln this case, the dough temperature is kept by cooled ingredients and temperature controlled water. The storage tanks are cleaned using rotating cleaning nozzles. The waste water can be discharged via separate outlets. The pipes are cleaned by a big cleaner. The big cleaner is put into the system through the launcher and is pushed to the receiver by water pressure. To return the big, compressed air is built up which moves it back to its starting position.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

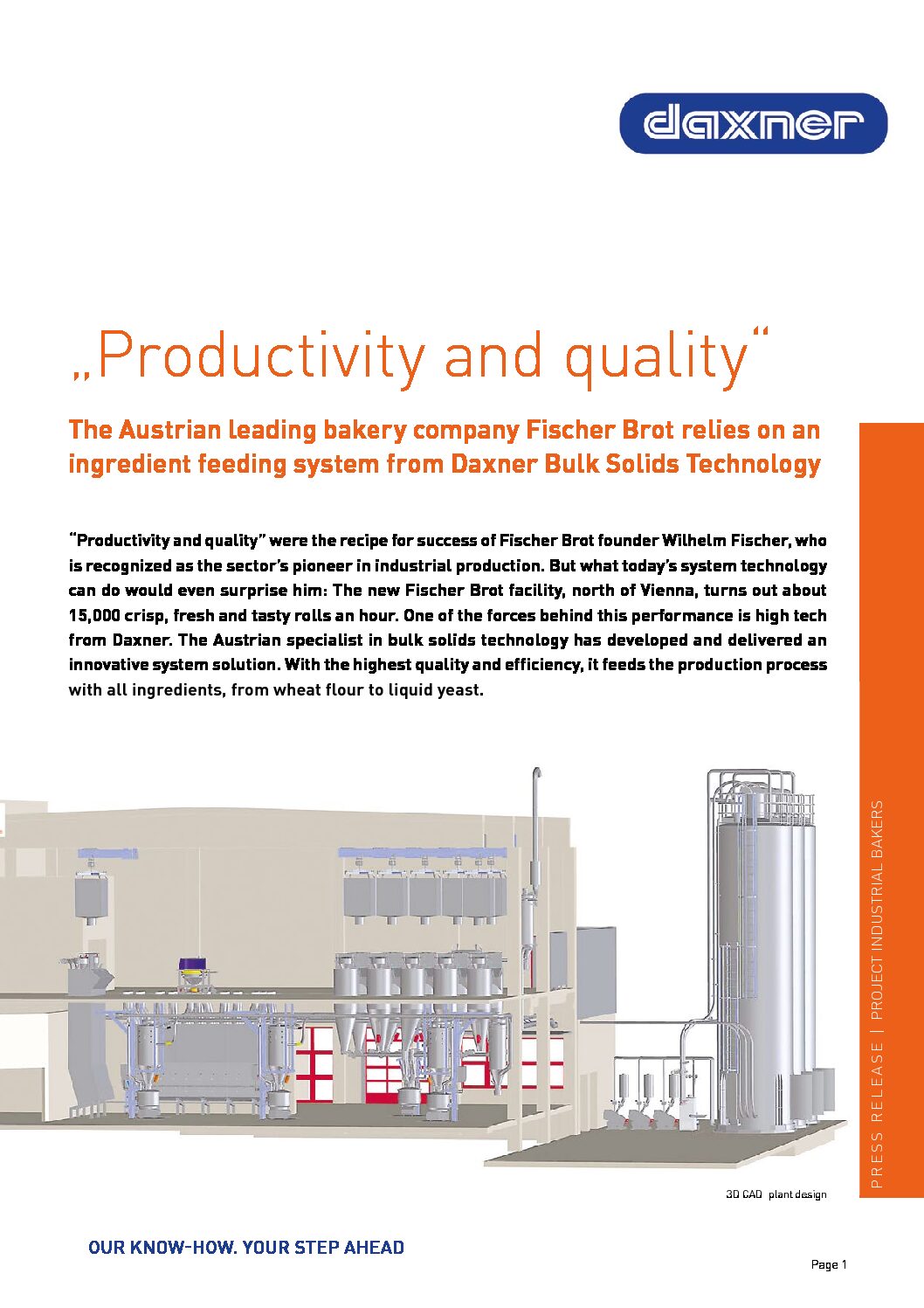

Efficient ingredient feeding system

An efficient ingredient feeding system for a leading bakery company: With the highest quality and efficiency, it feeds the production process with all ingredients, from wheat flour to liquid yeast.

Description

Handling of small, medium and large components

The Daxner system solution feeds all dough ingredients into the production process. They all have different bulk characteristics: The ingredients used come in powder, grain or liquid form and include wheat and rye flour, bread spices, salt and pumpkin seeds, as well as liquid yeast, oil and water. Furthermore the system developers were challenged with the varying quantity requirements, in order to find an efficient, cost-effective solution. Characteristic for the plant is a feeding system divided into four sub-areas tailored to large, medium and small components, as well as liquids. It feeds them into their corresponding batch-dough shell and transports the weighed and dosed ingredients to the kneader.

Fully automated feeding of large and medium components

The main dough ingredients, wheat and rye flour, are stored in three 65-cubic-metre aluminium outdoor silos. A silo head space dehumidifier prevents the formation of condensation. Pneumatic pressure conveys the flour to one of the four weighing bins with integrated filters, where the right quantities for each batch are weighed and dosed into the dough shell. In order to feed the three pneumatic conveyor lines to the weighing bins simultaneously (normally only possible as an option), the cone of each outdoor silo is equipped with its own fluidizing bin discharger. Besides increasing capacity, this technical detail increases system availability quite significantly.

The medium components, which are stored in Big bags, are fed by five Big bag discharge stations. They are stored in intermediate bins and dosed fully automated into the weighing bin or corresponding dough shell.

A manual dosing system for micro components

For small and micro components, Daxner has developed a very practical solution that is also efficient and cost-effective. A mobile bag dump station fills a total of 24 micro component cells, while three other cells are fed with Big bags. Using position sensors, the trolley is moved directly onto the small component cell to be loaded and is docked there pneumatically. Filling is performed completely dust free by using an aspiration system.

Dosing is done manually, but completely operator-controlled, guaranteeing a 100 percent traceability. An easy-to-read info terminal guides the operator to each manual component necessary for the batch and stipulates the exact dosage. If the wrong container lid is opened during removal, for example, the process is stopped immediately. The manual components are dosed into an intermediate bin which is positioned for precise weight determination on a mobile, high-resolution platform scale. With all of the precisely dosed and weighed small components, this is transported in sequence to the dough shell.

Proven in practice

The company has been using it for about many years to its complete satisfaction.

Moreover, the system is completely made of stainless steel. It meets not only the highest quality demands, but also the HACCP criteria and IFS standards.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

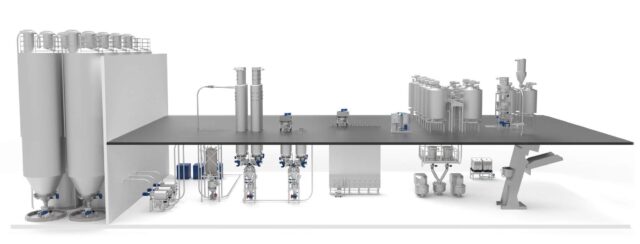

Automated ingredient handling

Major assignments – complex solutions

Daxner provides innovative bulk material handling, raw material handling, pneumatic conveying systems and mixer feeding.

These are exemplified by an efficient production line for industrial bakeries, which operates exclu-sively with Daxner components that handle several tonnes of flour and other ingredients hourly with competence all the way to the kneader. Our systems make sure that all recipe components reach the correct processing operation at the right time and in the right quantity.

Daxner offers complete packages for the entire production process for plants on this scale, which are designed for large numbers of charges and high hourly throughput: from intake and storage, through dosing and sifting up to weighing and proportioning of dry and liquid ingredients.

The in-company engineering department, as well as the entire Daxner team with its long-term experience and special know-how, stand for customised overall concepts, which convince with top quality and equally outstanding levels of plant availability.

Daxner only uses tried and tested components, which are combined to form an efficient overall solution that precisely meets your requirements. The basis is provided by a modular system, which in spite of a high degree of standardisation, nonetheless ensures exact, customised realisation. From this perspective, the systems furnish identical quality, functional perfection and the supply of optimum products. Otherwise, every system is as individual as your planned application. Moreover, if a secret recipe exists in this regard, then its ingredients consist of our comprehensive know-how and long-term experience in the bakery trade, which means that we are familiar with every need. You can trust equally in both this expertise and our reliability with respect to servicing, maintenance and spare parts supply.

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

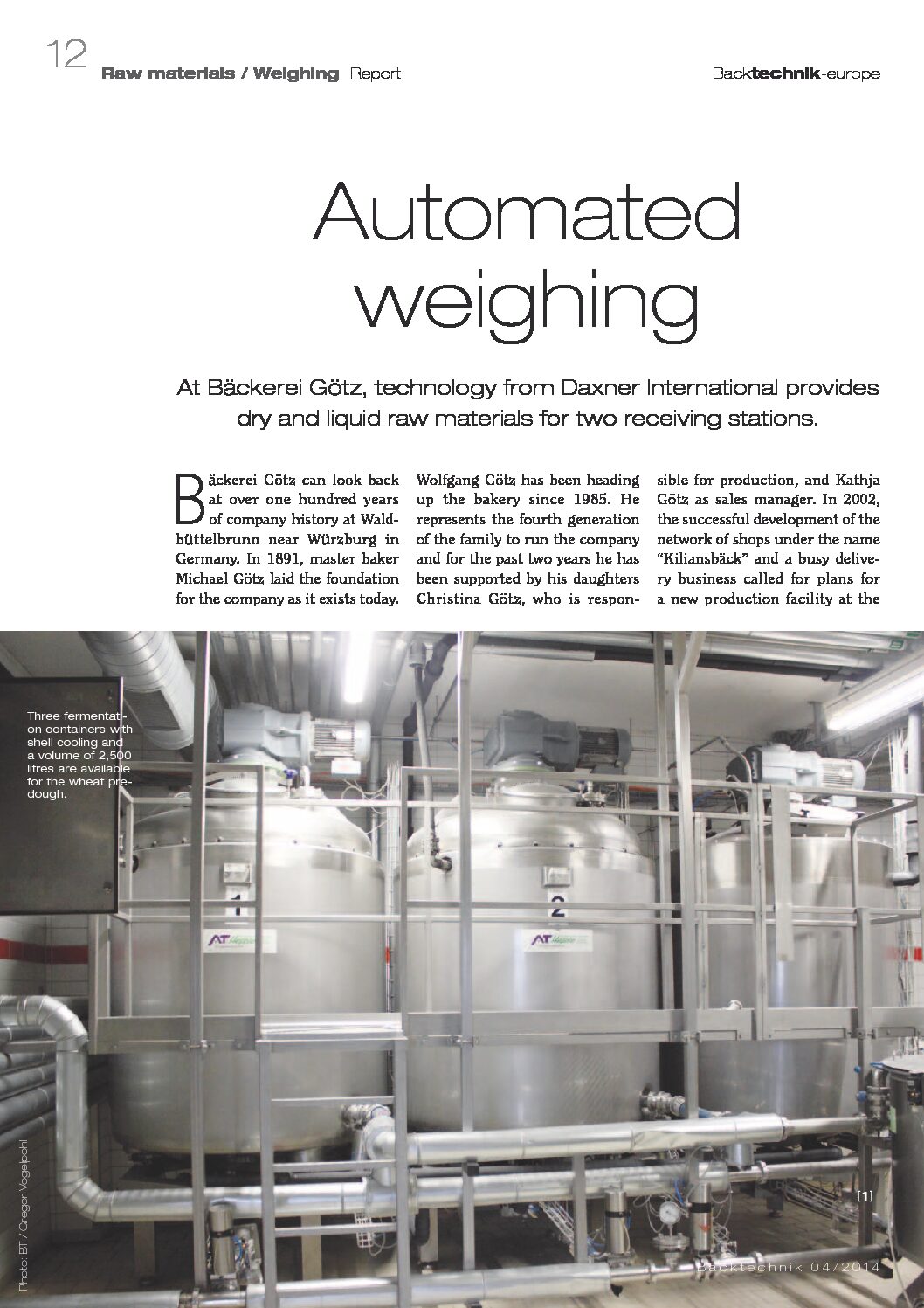

Highly automated plant with product innovations DAXDOU, DAXREC, DAXSOL

The successful bakery reached its capacity limits and invested in an innovative production facility with a high degree of automation. Technology from Daxner provides the handling of dry and liquid raw materials for two receiving stations.

Description

Together with the owner Daxner created a raw material weighing system which was tailored to the individual requirements of the bakery. The main focus was on a high degree of automation in raw materials provision to ensure the quality of the baked goods and also on a clear structure of the dough production area with particular attention to the essential issues – primarily hygiene.

Silos

The silo facility, equipped with suction pneumatics for flour transport, consists of 4 external silos with 30 t capacity each and 4 internal silos with around 5 t of flour each. The containers in the cylindrical silos are welded in one piece using strong aluminium sheet segments.

The flour is blown into the silos through a central filling station in the external area and then conveyed by 2 encapsulated aspirator fans into the 2 weighing containers – each with a capacity of 200 kilogrammes – which are installed in a room directly above the dough production. This is also where 2 dosing stations for small components are installed. Each is equipped with 8 stainless steel containers which can be easily filled with goods from bags from an access platform with steps and a safety rail.

They contain dry ingredients such as salt, raising agents as well as caraway and coriander, the bread spices typical of the Frankenland region. Each of the funnel shaped storage containers is equipped with its own frequency controlled conveyor screw in the lower section. This initially rotates at a higher speed to dose the main amount of the ingredient and then with slow rotations to carry out the fine measuring. The screw can achieve a weighing accuracy of about 10 grams.

The weighing units described are installed in duplicate and each supplies one receiving station in dough production – one for the bread range and the other for small baked goods and pastries. The dosed ingredients are transported through smooth downpipes, which offer little surface for dust to adhere, and the fixed extraction hood and finally into the vat. All supply lines for the liquid ingredients such as water, brine, liquid yeast and a creamy mass consisting of bread residue or wheat pre-dough are installed on the cover.

The water mixing and dosing system as well as the other storage containers for liquid components are housed in side rooms, leaving the rear wall of the dough production area to look very tidy. All supply lines exit from the wall in one central location which is clad with stainless steel. Only the swivel arm brackets for the 2 operator touch screens as well as the plug sockets for the telescopic spiral kneaders are visible on the tiled rear wall.

Liquid components

The room for pre-dough production and storage is located underneath the silo room, directly behind the dough production. The complex, fully automated plant essentially consists of 3 stainless steel proving and storage containers and the continuous Daxner pre-dough mixing system daxDou. This is used for intensive mixing of flour, water and additional ingredients – in this case the dough residue.

The pre-dough mixer is based on the principle of a continuous flow mixer and is equipped with kneading tools which were developed especially for dough production. The mixing tool can be moved out of the housing completely to facilitate cleaning. Wet cleaning is performed using an integrated high-pressure system via highpressure flat-spray nozzles. A container scale and a differential dosing scale are installed for continuous gravimetric flour addition. The dosing screw attached there continuously supplies the pre-dough mixer with the precise amount of flour and the water is dosed with a flow meter.

All systems are monitored and coordinated by the electronic control system. To ensure constantly fermented pre-doughs at any time of year, the double wall storage containers with 2,500 litres capacity each are equipped with a cooling water shell which is connected to a cooling water circuit. This allow precise control of all important dough parameters such as temperature, consistency and proving time using the computer control of the pre-dough mixing system.

A durable stainless steel mixer is attached to each of the proving containers. These mix the wheat pre-dough at fixed intervals and also allow processing of pre-doughs with low dough yield (dough yield of approx. 170). The tanks are filled from underneath so that no dough encrustations or flour dust can accumulate in the upper section.

Recently the bakery has also been processing bread residue into a ready-to-use creamy mass. A special process is used to liquidise the bread residue in the daxRec with a minimum amount of water and then crush the mixture in a rotor stator system using a special fine grinding technology. This creates a suspension which can be pumped and will not separate again, greatly facilitating storage in a cooled container.

Conclusion

Clear structures were created from raw materials receipt through to delivery and the individual production plants are set up in line. The compact size of the entire raw material supply section is also impressive.

Technology

- 4 external silos 30 tons

- 4 internal silos 5 tons

- 2 identical small component dosing stations

- daxDou continuous pre-dough mixer

- daxRec for processing bread/dough residue

- daxSol brine system

- yeast dissolver

- 3 fermentation containers with shell cooling and a volume of 2,500 litres

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

You must load the content of reCAPTCHA to submit the form. Please note that data will be exchanged with third-party providers.

More informationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information